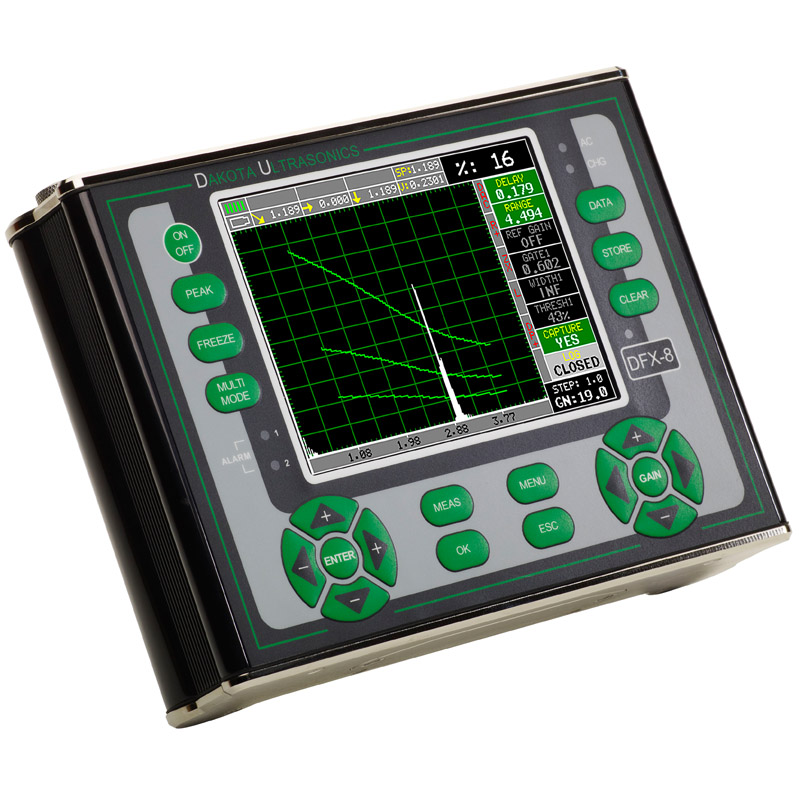

FX81-DL Flaw Detector and Ultrasonic Thickness Gauge

The DFX-8 has 4gb of internal memory to store readings in Grid or Sequential data formats. Data can be acquired via USB or SD card.

The DFX-8 combines the two types of gauges into one powerful and full featured instrument, that's equipped with a number of comprehensive toolkits to provide the user the arsenal necessary to address a number of common field applications.

Features

Flaw Detector

Thickness Gauge

Measurement Modes (Dual Element):

Measurement Modes (Dual Element):

Complete Kit

Specifications

| General | |

|---|---|

| Size | 8.5W x 6.5H x 2.5D in (216 x 165 x 70mm) |

| Weight | 4.5 lbs (2.04 kgs), with batteries |

| Case | Extruded aluminum body with nickel plated aluminum end caps (gasket sealed) |

| Display | Blanview sunlight readable QVGA TFT color display (320 x 240 pixels). Viewable area 4.54 x 3.40 in (115.2 x 86.4 mm), or 5.7 in (144.78 mm) diagonal. 16 color palette, multiple color options and variable brightness |

| Screen Refresh Rate | 60 Hz |

| Display Views | Flaw Detector: Full wave, +/- Rectified, or RF. Thickness Gauge: Digits, +/- Rectified, RF, or B-Scan |

| Timing | Precision TCXO timing with single shot 100 MHz 8 bit ultra low power digitizer |

| Measurement Gates | Two independent gates (Flaw), and three gates (thickness). Start & width adjustable over full range. Amplitude 5-95%, 1% steps. Positive or negative triggering for each gate with audible and visual alarms |

| Operating Temperature | 14 to 140F (-10C to 60C) |

| Environmental | Meets IP65 requirements |

| Lithium Ion Pack | 10.8v, 2 amp hrs, typical operation 18hrs |

| Battery Backup | Emergency battery backup. Six 1.5V alkaline, 1.2V AA Nicad cells, 1.2V AA NI-MH, or other other equivalent power source |

| Battery life (continuous use) | Alkaline (12 hrs), Nicad (5hrs), and NI-MH (12hrs), with default settings |

| Warranty | 2 years |

| Calibration | |

| Automatic Calibration | Longitudinal (straight), or Shear (angle) |

| Probe Types | Single Contact, Dual, Delay, and Angle |

| Units | English (in), Metric (mm), or Time (µs) |

| Velocity | 0.0100 to .6300 in/µs (256 - 16,000 m/s) |

| Test Range | 0 to 0.303in (7.70mm) minimum, to 1200in (30,480mm) maximum at steel velocity. Continuously variable |

| Zero Offset (Probe Zero) | 0 - 999.999 µs |

| Material Velocity Table | Contains longitudinal and shear velocities for a variety of material types |

| Pulser | |

| Pulser Type | Two adjustable square wave pulsers and receivers |

| P.R.F. | 8 to 2000Hz in selectable steps (8, 16, 32, 66, 125, 250, 333, 1000, 2000Hz) |

| Pulser Voltage | 100 - 200 volt peak amplitude, rise/fall time < 10ns into 50ohm |

| Pulse Width | 40 to 400 ns. Selectable step options 40, 80 & 400 ns (labeled spike, thin and wide) |

| Receiver | |

| Gain | 0 to 110dB with 0.2dB resolution. Manual and AGC control |

| Damping | 50, 75, 100, 300, 600, & 1500 ohms |

| Frequency Bands |

Broadband 1.8 – 19 MHz (-3dB). Four narrow bands at 1MHz, 2MHz, 5MHz, 10MHz DFX-8+ additional narrow bands at 0.5 & 15MHz |

| Horizontal Linearity | ± 0.4% FSW |

| Vertical Linearity | ± 1% FSH |

| Amplifier Linearity | ± 1 dB |

| Amplitude Measurement | 0 to 100% FSH, with 1% resolution |

| Delay | 0 - 999in (25,375mm) at steel velocity |

| Memory | |

| Log Formats | Grid (Alpha Numeric), or Sequential (Auto Identifier) |

| Memory | 4 Gb internal and up to 64 Gb External SD slot |

| Screen Capture | Bitmap graphic capture for quick documentation |

| Custom Setups | 64 user configurations |

| Video | |

| Remote Commander | Java PC software allows remote display and control for training/presentation purposes, and custom system integration |

| Transducers | |

| Delay Line | High Frequency single element delay line style for precision testing of thin materials |

| Pencil | High Frequency single element delay line style for testing of materials in tight access areas and difficult geometries |

| Contact | Single element contact style for general purpose longitudinal & Shear wave flaw detection |

| Dual | Pitch/Catch dual element style for longitudinal and Shear wave corrosion inspections |

| Certification | |

| Thickness Gauge | Factory calibration traceable to NIST & MIL-STD-45662A |

| Flaw Detector | EN12668-1 compliant |